The Sharpener Showdown

Sharp tools are an essential part of any woodworker’s shop. Today with the current hand tool movement, they are even more critical. There are literally hundreds of products out there to sharpen your tools, so to review them all would be impractical if not impossible. In the past few months, we have evaluated and published articles on several fine methods of sharpening your hand tools saw blades, and router bits; I was still in search of more. I wanted to be able to sharpen any tool in my workshop. While I haven’t found a way as of yet to do a great sharpening on my saw blades, I was able to use the Trend Diamond file to dress the blades.

Another set of tools that drives me insane are my drill bits. I am weary of having to constantly buy new ones to replace the bits that are dull, and I don’t have a great answer for my brad point bits. With this in mind I began a search of the best sharpening systems, and then chose the ones that seemed like they would meet my needs.

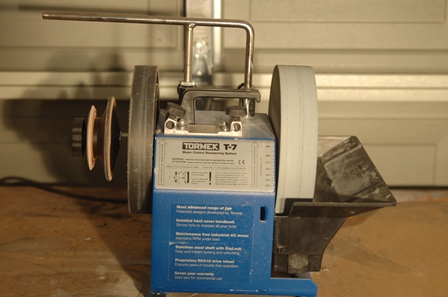

I decided first and foremost it was important to get my hands on a Tormek T7, a highly rated system. A few phone calls to Europe got me a U.S. contact at Affinity Tool Works. I was loaned a fully loaded T7. Next the Jet sharpener was in my sites; I was unable to get a loaner tool from Jet, which was a bit of a drag. However, with some serious time on EBay I was able to get two of the JSSG-10 models for a very good price and I also purchased several accessories well below retail on EBay. Next I contacted Work sharp, the people that make the Drill Dr. I was given a fully loaded Work Sharp 3000 with all the bells and whistles to add to the test. Lastly I was able to get a copy of the Grizzly T100. Now, the field was set for a serious head to head test.

I have recently been bitten by the hand-plane bug and have been restoring hand planes or conserving those that are in good condition but were a bit rusty or dirty. One thing is for sure, in the hundreds of planes I have purchased; only 2 were sharp enough to use and neither one of them were as sharp as I wanted. I decided to begin the tests by sharpening plane irons.

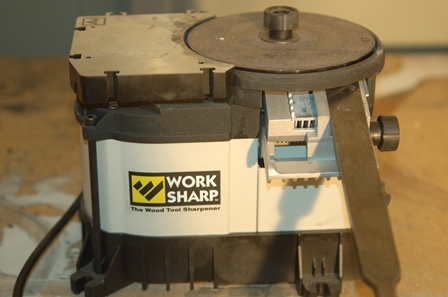

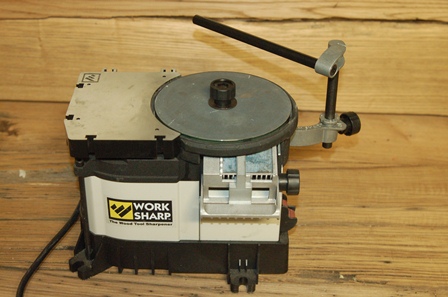

The first tool I used was the work Sharp 3000. It is a unique machine that uses the Scary sharp method of putting abrasive paper on a piece of tempered glass. I sharpened several plane irons on the WS-3000 with very good results and I was pleased with the performance. The only thing I didn’t like was that you had to insert the blade in the sharpening port and pull it out several times over and over again. This is how you sharpen on the Work Sharp with the factory abrasives. I will add more on the aftermarket abrasives later. Next came large irons and these were sharpened with the wide blade attachment; it uses a jig to hold the iron, this worked very well. I was really starting to like this little machine.

The first tool I used was the work Sharp 3000. It is a unique machine that uses the Scary sharp method of putting abrasive paper on a piece of tempered glass. I sharpened several plane irons on the WS-3000 with very good results and I was pleased with the performance. The only thing I didn’t like was that you had to insert the blade in the sharpening port and pull it out several times over and over again. This is how you sharpen on the Work Sharp with the factory abrasives. I will add more on the aftermarket abrasives later. Next came large irons and these were sharpened with the wide blade attachment; it uses a jig to hold the iron, this worked very well. I was really starting to like this little machine. Now it was time to do some chisels on the Work Sharp 3000. I had purchased a load of old, battered chisels for the test and sharpened ten of them on the Work Sharp; it continued to impress me. All these blades were sharpened without having to change paper, but it was now time to change the course paper. This was the second thing that was a bit of a drag because the adhesive is so strong on the paper it shredded it to pieces, so I had to use a razor blade to clean up the mess on the glass. Although, it could be that I over used the paper; I would not take the next paper down as far next time.

Next came some turning tools. Using the Work Sharp for these, you place a slotted disk on the machine. The machine comes with three of these discs and the manufacturer sent me a couple of extras. I feel it is a good idea to get the extra discs; it makes things a lot easier. Doing the turning tools on the Work Sharp is very cool indeed. As the disc spins, you can see the tool through the slots in the discs. Be sure your sharpening area is well lit; this makes it easier to see what you are doing. The ability to repeat the sharpening process is pretty easy; I found that you removed more material on your turning tools than you do on other types of blades. This was fairly minor and really not a big issue. As your skill with the Work Sharp improves it is a fun tool to use, which I found to be a plus. Another great feature of the ws3000 is that it has a belt sharpener a lot like the one we tried to get from Sorby. This is a wonderful way to sharpen many tools including scissors. The big downfall with the Work Sharp is it won’t sharpen jointer or planer blades. Other than that, I loved the machine. It is quick to use and hones things very well. If you don’t want a hallow grind on a chisel this is the right tool. I rated this tool 2nd among the four machines I tested.

Next came some turning tools. Using the Work Sharp for these, you place a slotted disk on the machine. The machine comes with three of these discs and the manufacturer sent me a couple of extras. I feel it is a good idea to get the extra discs; it makes things a lot easier. Doing the turning tools on the Work Sharp is very cool indeed. As the disc spins, you can see the tool through the slots in the discs. Be sure your sharpening area is well lit; this makes it easier to see what you are doing. The ability to repeat the sharpening process is pretty easy; I found that you removed more material on your turning tools than you do on other types of blades. This was fairly minor and really not a big issue. As your skill with the Work Sharp improves it is a fun tool to use, which I found to be a plus. Another great feature of the ws3000 is that it has a belt sharpener a lot like the one we tried to get from Sorby. This is a wonderful way to sharpen many tools including scissors. The big downfall with the Work Sharp is it won’t sharpen jointer or planer blades. Other than that, I loved the machine. It is quick to use and hones things very well. If you don’t want a hallow grind on a chisel this is the right tool. I rated this tool 2nd among the four machines I tested.  Next I worked with the Jet jssg10. It is a very nice looking machine, with a pretty white paint job and the great 2 drawer add-on base. I added the lazy-Susan style swivel locking base, making the machine fairly tall. It will require a lower bench to work on it comfortably unlike the other systems. The Jet boasts a variable speed control and an adjustable torque setting; all really good ideas. They also claim the machine is safer because of the closed-in base. After reading other reviews, I thought the Jet would be a great machine. I started with truing the wheel. The truing jig is poorly designed and after a while I was frustrated and stopped and simply used the Tormek Jig to dress the wheel. I started on a plane blade and when I applied pressure to the blade, the motor slowed down significantly. I raised the speed up and adjusted the torque and still the wheel slowed significantly. Feeling this was as good as I was going to get out of the jssg10, I went ahead and sharpened the plane irons,

Next I worked with the Jet jssg10. It is a very nice looking machine, with a pretty white paint job and the great 2 drawer add-on base. I added the lazy-Susan style swivel locking base, making the machine fairly tall. It will require a lower bench to work on it comfortably unlike the other systems. The Jet boasts a variable speed control and an adjustable torque setting; all really good ideas. They also claim the machine is safer because of the closed-in base. After reading other reviews, I thought the Jet would be a great machine. I started with truing the wheel. The truing jig is poorly designed and after a while I was frustrated and stopped and simply used the Tormek Jig to dress the wheel. I started on a plane blade and when I applied pressure to the blade, the motor slowed down significantly. I raised the speed up and adjusted the torque and still the wheel slowed significantly. Feeling this was as good as I was going to get out of the jssg10, I went ahead and sharpened the plane irons, The Jet did a very good job, except the jig, again, had a problem. It was not square and required filing to make it square. I even purchased a second jig, and found the second one was different. It had a high shine chrome finish. I was able to get good results with the second jig. Then, I had purchased a jig called a Camber jig. This jig, again, was high quality and worked very well. The jig lets you put a slightly arched surface on the plane irons very precisely; a major winner for the jet.

It was time to do turning tools on the Jet. The jig for these was also well thought out as it performed very well with a great deal of repeatability. I really like the jig for gouges and skew chisels especially. I was able to make clean precise grinds and was pleased except for the lack of power in the motor. The Jet was great, but the power is a huge problem. It was at this point that I purchased the second unit to see if this was not an issue with this particular unit or if it was common in the Jets. I am sad to say the performance of the second JCGS-10 was exactly the same as the first one. It being so under powered moved it to a disappointing 3rd place in the test. Again, we sharpened many items over the four months of the test. I assure you the Jet could be a great machine if the motor was reworked and made stronger. I have been in contact with Jet on this matter and they are fully aware of our findings.

The Grizzly T100-10 came up next. This unit sells for the lowest price in the test. Unfortunately it lacked detailed documentation, and only came with one jig. My mission was to test the sharpener and it performed about the same as the Jet, however it had none of the great add-ons that Jet offered, like the lazy Susan, so you have to lift the unit up and pivot it around every time you go from sharpening to honing. You will be pleased with the price point of this unit, but know in advance the jig I had was of low quality and requiring filing to straighten it out, and again I turned to the Tormek’s jig to true up the grinding wheel. The Tormek truing tool was by far the best in the test. The strop on the Grizzly was almost the same as on the Jet. It is light weight and has a small wobble in it. However, the only major troubles with the Grizzly are #1 it is also under powered and 2nd, the water tray is very difficult to install and use. I did notice that the Grizzly had the easiest power switch to use, although it was not as water proof like the Tormek or the Jet. The Work Sharp’s switch was the easiest to use. I put over 40 hours on the Grizzly and have no major concerns other than the two problems I mentioned above. This machine may sell a ton of units because of its price alone and if you only sharpen a couple tools a day, it will meet your needs nicely. I do suggest you buy the jigs from another source however, with the possible exception of the planer blade jig which I have not tested. If you want a camber jig, it’s the Jet’s you want. Although If its an ax jig or a good planer iron jig, you’ll want either the Tormek or a Jet model. Be prepared to spend more on jigs than you did for the whole unit as you will need these jigs to accomplish the tasks you got the machine for in the first place. I was highly pleased with

The Grizzly T100-10 came up next. This unit sells for the lowest price in the test. Unfortunately it lacked detailed documentation, and only came with one jig. My mission was to test the sharpener and it performed about the same as the Jet, however it had none of the great add-ons that Jet offered, like the lazy Susan, so you have to lift the unit up and pivot it around every time you go from sharpening to honing. You will be pleased with the price point of this unit, but know in advance the jig I had was of low quality and requiring filing to straighten it out, and again I turned to the Tormek’s jig to true up the grinding wheel. The Tormek truing tool was by far the best in the test. The strop on the Grizzly was almost the same as on the Jet. It is light weight and has a small wobble in it. However, the only major troubles with the Grizzly are #1 it is also under powered and 2nd, the water tray is very difficult to install and use. I did notice that the Grizzly had the easiest power switch to use, although it was not as water proof like the Tormek or the Jet. The Work Sharp’s switch was the easiest to use. I put over 40 hours on the Grizzly and have no major concerns other than the two problems I mentioned above. This machine may sell a ton of units because of its price alone and if you only sharpen a couple tools a day, it will meet your needs nicely. I do suggest you buy the jigs from another source however, with the possible exception of the planer blade jig which I have not tested. If you want a camber jig, it’s the Jet’s you want. Although If its an ax jig or a good planer iron jig, you’ll want either the Tormek or a Jet model. Be prepared to spend more on jigs than you did for the whole unit as you will need these jigs to accomplish the tasks you got the machine for in the first place. I was highly pleased with  the overall performance of the Grizzly; it is a solid unit for the price.

the overall performance of the Grizzly; it is a solid unit for the price. Last I came to the Tormek T7. This one is not cheap although you can see the quality everywhere starting with the box it came in. The first thing you find is a guide to unpacking the Tormek and I recommend you follow this guide carefully. The base unit contains all the jigs you need to get started. I went very slowly through this process when I noticed the books. This was a good hour plus of essential reading. I was very pleased that every aspect of wet grinding you could ever imagine was covered. This impressed me quite a lot. Next there were even DVDs and that took another couple of hours of watching time, however when I was done I felt I knew what I was doing. The Tormek’s books and DVDs are a great resource that stands out in the test.

The Tormek was surprisingly light yet it was by far the most powerful machine in the test. I started in on the planer irons on the Tormek. As my technique got better, the results came faster and faster. I am able to take an iron with a large  chip in the blade and have it to a mirror finish in less then seven minutes. I know that some of you will be faster and some slower as I consider myself a little above average on most machines and I became very good on this machine. I have logged 50 hours of sharpening on the Tormek and I have sharpened axes, planer blades, chisels, knives, including planer knives as large as the 13 inch from DeWalt and the Powermatic jointer knives from the 54a jointer. I spent about 10 hours sharpening drill bits on the Tormek Drill Jig which eliminated the need to buy brad point bits all together since you can grind a 4 faceted drill on the Tormek. I tested every wheel available for the T7 and can assure you the competition has no answer for the Japanese whetstone or the Black stone for high speed steel. I sharpened my fine Japanese sushi knife and the finish is awesome! It literally slices through the paper without distorting the paper like an infomercial trick, but I was doing it myself with these great results! I was so excited I turned to my favorite personal tools the Rob Cosman IBC Blades that I love so much and I sharpened them on the Tormek and the edge was second to none. The shaving I get off an old bedrock plane with this blade is good-as- factory results and was even better with the blade sharpened on the Tormek. It glided through the wood like it wasn’t even cutting and yet shavings so thin you can see through them were coming off my 110 year old bedrock plane. This tells me the blade is good but also the blade is beyond sharp; it is a perfect edge. Nothing else in the test was even close.

chip in the blade and have it to a mirror finish in less then seven minutes. I know that some of you will be faster and some slower as I consider myself a little above average on most machines and I became very good on this machine. I have logged 50 hours of sharpening on the Tormek and I have sharpened axes, planer blades, chisels, knives, including planer knives as large as the 13 inch from DeWalt and the Powermatic jointer knives from the 54a jointer. I spent about 10 hours sharpening drill bits on the Tormek Drill Jig which eliminated the need to buy brad point bits all together since you can grind a 4 faceted drill on the Tormek. I tested every wheel available for the T7 and can assure you the competition has no answer for the Japanese whetstone or the Black stone for high speed steel. I sharpened my fine Japanese sushi knife and the finish is awesome! It literally slices through the paper without distorting the paper like an infomercial trick, but I was doing it myself with these great results! I was so excited I turned to my favorite personal tools the Rob Cosman IBC Blades that I love so much and I sharpened them on the Tormek and the edge was second to none. The shaving I get off an old bedrock plane with this blade is good-as- factory results and was even better with the blade sharpened on the Tormek. It glided through the wood like it wasn’t even cutting and yet shavings so thin you can see through them were coming off my 110 year old bedrock plane. This tells me the blade is good but also the blade is beyond sharp; it is a perfect edge. Nothing else in the test was even close.

chip in the blade and have it to a mirror finish in less then seven minutes. I know that some of you will be faster and some slower as I consider myself a little above average on most machines and I became very good on this machine. I have logged 50 hours of sharpening on the Tormek and I have sharpened axes, planer blades, chisels, knives, including planer knives as large as the 13 inch from DeWalt and the Powermatic jointer knives from the 54a jointer. I spent about 10 hours sharpening drill bits on the Tormek Drill Jig which eliminated the need to buy brad point bits all together since you can grind a 4 faceted drill on the Tormek. I tested every wheel available for the T7 and can assure you the competition has no answer for the Japanese whetstone or the Black stone for high speed steel. I sharpened my fine Japanese sushi knife and the finish is awesome! It literally slices through the paper without distorting the paper like an infomercial trick, but I was doing it myself with these great results! I was so excited I turned to my favorite personal tools the Rob Cosman IBC Blades that I love so much and I sharpened them on the Tormek and the edge was second to none. The shaving I get off an old bedrock plane with this blade is good-as- factory results and was even better with the blade sharpened on the Tormek. It glided through the wood like it wasn’t even cutting and yet shavings so thin you can see through them were coming off my 110 year old bedrock plane. This tells me the blade is good but also the blade is beyond sharp; it is a perfect edge. Nothing else in the test was even close.

chip in the blade and have it to a mirror finish in less then seven minutes. I know that some of you will be faster and some slower as I consider myself a little above average on most machines and I became very good on this machine. I have logged 50 hours of sharpening on the Tormek and I have sharpened axes, planer blades, chisels, knives, including planer knives as large as the 13 inch from DeWalt and the Powermatic jointer knives from the 54a jointer. I spent about 10 hours sharpening drill bits on the Tormek Drill Jig which eliminated the need to buy brad point bits all together since you can grind a 4 faceted drill on the Tormek. I tested every wheel available for the T7 and can assure you the competition has no answer for the Japanese whetstone or the Black stone for high speed steel. I sharpened my fine Japanese sushi knife and the finish is awesome! It literally slices through the paper without distorting the paper like an infomercial trick, but I was doing it myself with these great results! I was so excited I turned to my favorite personal tools the Rob Cosman IBC Blades that I love so much and I sharpened them on the Tormek and the edge was second to none. The shaving I get off an old bedrock plane with this blade is good-as- factory results and was even better with the blade sharpened on the Tormek. It glided through the wood like it wasn’t even cutting and yet shavings so thin you can see through them were coming off my 110 year old bedrock plane. This tells me the blade is good but also the blade is beyond sharp; it is a perfect edge. Nothing else in the test was even close. I then played with everything I could think of to sharpen- I did the axe, the lawnmower blade, the maul, all my wives kitchen knives and the results were always the same, the Tormek is the clear winner of this test and not just by a little. It is twice as good as anything else we tested as it performs faster, with less wasted material than the others. The jigs are the best overall; the only jig that was in the same class was the camber jig from Jet,which I am sure Tormek will have their own version of soon. Another review I read said the Jet said was the best at splash control; however the Tormek has a new water trough and is easily as good as the Jet’s. It has this great little feature of moving three magnetic feet to angle the water flow to the trough. I ran the Tormek for five straight hours one evening and it never bogged down at all. The motor is powerful and the jigs are simply the best I tested and the whole thing was not that much more in price than the Jet once you buy all the jigs that the Tormek came with, if you want the best machine for the money then look no further than the Tormek T7 for any tool you need to

I then played with everything I could think of to sharpen- I did the axe, the lawnmower blade, the maul, all my wives kitchen knives and the results were always the same, the Tormek is the clear winner of this test and not just by a little. It is twice as good as anything else we tested as it performs faster, with less wasted material than the others. The jigs are the best overall; the only jig that was in the same class was the camber jig from Jet,which I am sure Tormek will have their own version of soon. Another review I read said the Jet said was the best at splash control; however the Tormek has a new water trough and is easily as good as the Jet’s. It has this great little feature of moving three magnetic feet to angle the water flow to the trough. I ran the Tormek for five straight hours one evening and it never bogged down at all. The motor is powerful and the jigs are simply the best I tested and the whole thing was not that much more in price than the Jet once you buy all the jigs that the Tormek came with, if you want the best machine for the money then look no further than the Tormek T7 for any tool you need to  sharpen. None of the other’s had a drill Jig and none of the other units had a dresser with a screw advance. The other units lacked the three stones giving you such a varied array of sharpening options. There were also several features on the T7 that make it superior; it has a stainless steel shaft and the nut is stainless steel as well. There is a magnet in the water trough that holds the filings from re circulating through the water and gouging up the tool you are sharpening. The finish on the machine is a special product that resists corrosion and the motor is very powerful and has great torque. The Tormek has the most jigs and they all work as they are supposed to- we didn’t have to dial them in by hand as this was already done by Tormek. The only thing I was left wanting for this tool was a lazy- Susan and camber jig. For now I’ll use the Jet camber jig, as all the jigs on the 3 wet grinders are interchangeable and I have asked Tormek to make a lazy- Susan to aid in turning the machine around .

sharpen. None of the other’s had a drill Jig and none of the other units had a dresser with a screw advance. The other units lacked the three stones giving you such a varied array of sharpening options. There were also several features on the T7 that make it superior; it has a stainless steel shaft and the nut is stainless steel as well. There is a magnet in the water trough that holds the filings from re circulating through the water and gouging up the tool you are sharpening. The finish on the machine is a special product that resists corrosion and the motor is very powerful and has great torque. The Tormek has the most jigs and they all work as they are supposed to- we didn’t have to dial them in by hand as this was already done by Tormek. The only thing I was left wanting for this tool was a lazy- Susan and camber jig. For now I’ll use the Jet camber jig, as all the jigs on the 3 wet grinders are interchangeable and I have asked Tormek to make a lazy- Susan to aid in turning the machine around .

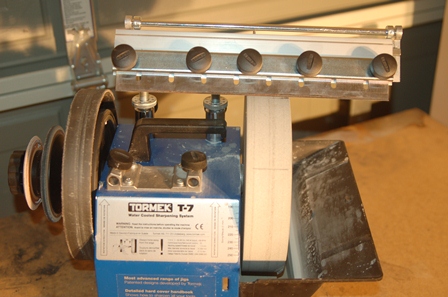

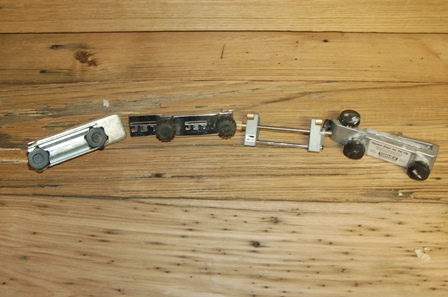

Here is a photo of all the plane iron straight edge jigs. These are from left to right in quality the grizzly, the jet, the worksharp, and the Tormek. These can be used for chisels as well as plane irons. I was not happy with the jet and the grizzly.

As you build your sharpening arsenal, please buy the best tools you can afford. It will lower your frustration while sharpening, improve your woodworking, and make you a safer woodworker. Remember, dull tools are dangerous tools. Be sure to check out our other articles and product reviews on sharpening tools.

Lance Granum

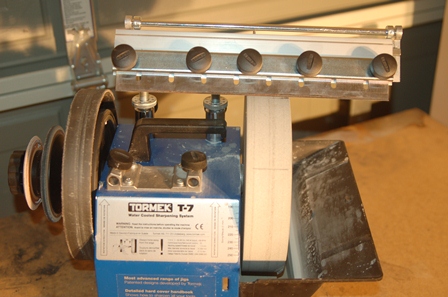

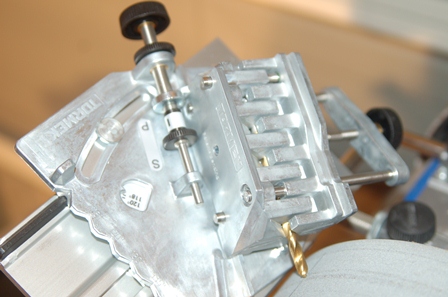

Lance Granum After this review was done I was sent a new jig for the worksharp3000 that lets you use Tormek jigs on it. I have not had the chance to test it but here is a photo of the work sharp with the new jig.