Home - This Old Workshop

Dewalt 780 Compound Sliding Miter Saw

When I began the test on the DeWalt DWS 780 12” double bevel sliding compound miter saw the classic yellow and black colors carried with it a prejudice towards quality and durability due to my experience with their tools in the past. I did my best to clear these expectations from my mind in order to give this tool a proper test. So I pulled up my sleeves to tackle it with a clear mind and did my best to remove all expectations from my head.

When I began the test on the DeWalt DWS 780 12” double bevel sliding compound miter saw the classic yellow and black colors carried with it a prejudice towards quality and durability due to my experience with their tools in the past. I did my best to clear these expectations from my mind in order to give this tool a proper test. So I pulled up my sleeves to tackle it with a clear mind and did my best to remove all expectations from my head.

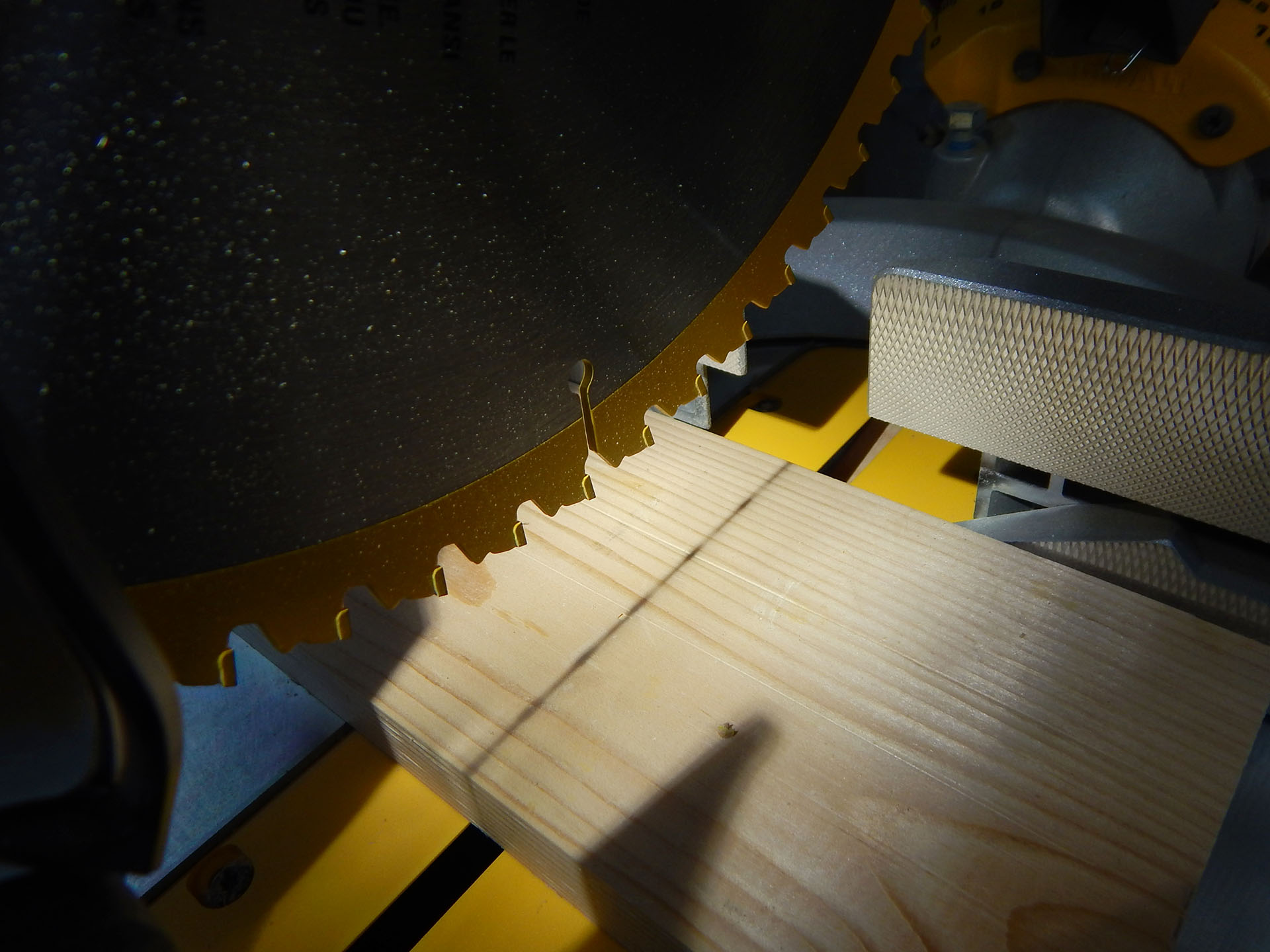

The saw slides along twin rails that proved to be smooth and accurate. I think these will need to be kept clean but that’s to be expected and no different than other saws of this type. I could force the blade out of adjustment with moderate side to side pressure but why would you do that, just pull straight. I saw a comment on someone else review of a SCMS and they claimed they could move the saw out of alignment by pushing the handle like this so I wanted to try it on this model but somehow it seems like a non-problem as long as it’s not easily moved. I noticed no run out over the length of the saw’s 16” maximum capacity when using the back fence and the zero stop was right on every time I snapped it into place.

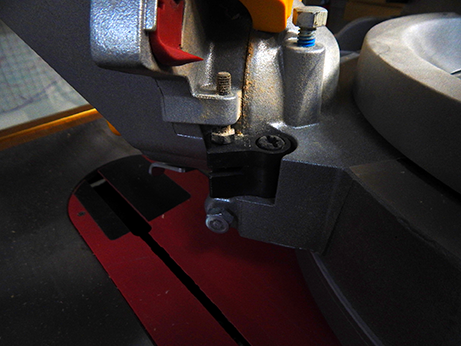

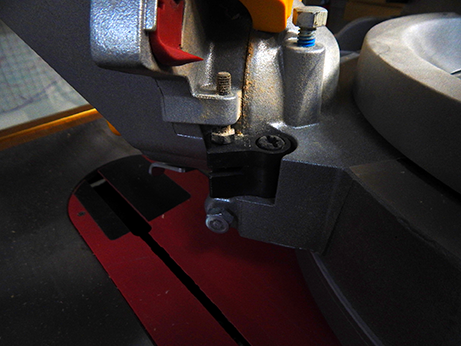

As with any sliding compound miter saw, the stops are crucial to make cutting easy and repeatable. The DeWalt 780 provides no less than 16 different predefined stops and locking positions. Out of the box accuracy was also notable. I didn’t have to adjust a single one to bring the saw stops true. You can even make the bevel stops into metric measurements by flipping over the stops. The miter stops are made from metal rather than the plastic stops I have seen in other brands. Plastic is easier to disfigure so this is a great design feature.

As with any sliding compound miter saw, the stops are crucial to make cutting easy and repeatable. The DeWalt 780 provides no less than 16 different predefined stops and locking positions. Out of the box accuracy was also notable. I didn’t have to adjust a single one to bring the saw stops true. You can even make the bevel stops into metric measurements by flipping over the stops. The miter stops are made from metal rather than the plastic stops I have seen in other brands. Plastic is easier to disfigure so this is a great design feature.

DeWalt states the new design for the dust skirt can grab 75% of the dust so I made over two dozen cuts, swept up the bench and compared it to the volume in the catch bag. I would call it more like 60% but it caught a good percent of the dust and I am confident when connected to my dust collection it will do a great job. The catch bag position is one thing I didn’t like. Sticking straight out of the back past the carriage arms it extends the depth of the unit an extra 10” bringing the footprint to a 44” deep, which can matter in smaller shops like mine.

DeWalt states the new design for the dust skirt can grab 75% of the dust so I made over two dozen cuts, swept up the bench and compared it to the volume in the catch bag. I would call it more like 60% but it caught a good percent of the dust and I am confident when connected to my dust collection it will do a great job. The catch bag position is one thing I didn’t like. Sticking straight out of the back past the carriage arms it extends the depth of the unit an extra 10” bringing the footprint to a 44” deep, which can matter in smaller shops like mine.

One of the features of the DeWalt 780 that caught my eye was its blade position marker. To mark the cut line The 780 has the XPS Cross cut positioning system, a pair of LED lights under the guard that shine onto the blade and create a shadow showing the cut location no matter what the kerf size of your blade is. Now I have always been a lover of high-tech things and lasers have always impressed me, the thought of something as old school as a shadow created some skepticism in my mind, but it marks the cuts accurately each time. One of my chief concerns was how well it would show up in bright light so I used several lights around the saw to see if the shadow would fade significantly enough to make it hard to see which it did not. The last test for the XPS was in bright sunlight since this saw is a portable jobsite saw. Folding up the saw I carried it outside, the 56 pounds was heavy for an older guy like myself. After all that I am happy to say the XPS was still visible on the cut line in the sun. A little harder to see outside but it marks the line just fine.

I am very happy with the DeWalt DWS 780’s features and quality. It is one I plan to use over the other models in my shop. Retailing for around $599 it is an affordable investment for your shop and should perform well for you and be a welcome member of your tool inventory and believe me a 12” saw is worth the investment over a 10” saw in my opinion. Why limit your capacity when it is really not that much more for the larger models.

I am very happy with the DeWalt DWS 780’s features and quality. It is one I plan to use over the other models in my shop. Retailing for around $599 it is an affordable investment for your shop and should perform well for you and be a welcome member of your tool inventory and believe me a 12” saw is worth the investment over a 10” saw in my opinion. Why limit your capacity when it is really not that much more for the larger models.

Daniel